“Every masterpiece begins with a single stitch, and in the heart of Lucknow, Chikankari artisans weave magic into fabric.”

Chikankari, the soul of Lucknow’s textile heritage, is not just an embroidery style—it’s a labor of love. Each piece goes through a meticulous process that transforms plain fabric into a work of art. From designing to the final washing, multiple artisans contribute at different stages, ensuring that every stitch tells a story.

Let’s take a deep dive into how Authentic Chikankari is made, following the journey from thread to masterpiece.

📌 Step 1: Designing & Block Printing

Before embroidery begins, the artisan first conceptualizes the design. Traditionally, designs are inspired by Mughal motifs, floral patterns, paisleys, and nature.

🔹 Block Printing Process:

These outlines serve as guidelines for the embroiderers, marking where the stitches will go.

The base fabric (cotton, silk, georgette, etc.) is spread on a flat surface.

Wooden blocks dipped in Geru (earth dye) or neel (indigo dye) are stamped onto the fabric.

Did You Know?

Earlier, artisans used natural dyes made from herbs and plant extracts, but modern Chikankari often uses chemical dyes for better durability.

📌 Step 2: The Magic of Hand Embroidery

Once printed, the fabric moves to skilled artisans—mostly women who work from home—to begin the embroidery.

🔹 Chikankari Stitching Techniques:

Jali Work: Creates a lace-like effect without cutting the fabric

Flat Stitches: Tepchi (running stitch), Bakhia (shadow work)

Embossed Stitches: Murri (rice grain-like knots), Phanda (pearls).

Each stitch is done by hand, giving every piece a one-of-a-kind texture and depth.

Did You Know?

A single piece of Authentic Chikankari can take several weeks to months to complete, depending on the complexity of the design!

📌 Step 3: Washing & Bleaching – The Final Transformation

Once the embroidery is finished, the fabric undergoes an intensive washing process to remove the block print outlines.

🔹 Washing Process:

Artisans use a mix of natural and chemical bleaching to ensure a crisp, clean finish.

The fabric is soaked in water for a few hours.

It is rubbed with soap and beaten on stone slabs to clear the dye.

Did You Know?

Traditional Chikankari bleaching involved goat dung and river water, believed to enhance the fabric’s softness and shine!

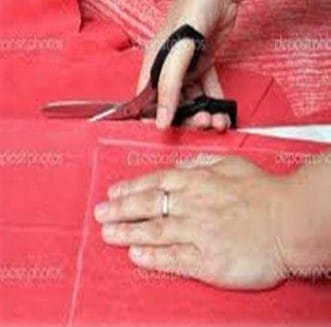

📌 Step 4: Cutting, Stitching & Finishing

The washed fabric is then cut into different garment styles—kurtas, sarees, dupattas, lehengas, and more.

🔹 Finishing Touches:

Some pieces are dyed in pastel shades for a modern touch

Any loose threads are trimmed

The fabric is ironed to bring out its full beauty.

At this stage, the Chikankari masterpiece is finally ready for the world to admire!

Why Handmade Chikankari is So Special

Unlike machine embroidery, Authentic Lucknowi Chikankari is a blend of skill, patience, and artistry. Every step, from printing to embroidery and finishing, is done by hand, making each piece unique and irreplaceable.

🌸 A single piece passes through multiple artisans, each adding their expertise.

🌸 No two handmade Chikankari outfits are exactly the same.

🌸 The real beauty lies in its imperfections—each thread woven with dedication.

Final Thoughts: A Heritage Worth Preserving

From a simple fabric to a luxurious handcrafted masterpiece, Chikankari undergoes an extraordinary journey before it reaches your wardrobe.

At Oudh Creations, we take pride in preserving this heritage craft, ensuring that each piece is created with the same love and precision as it was centuries ago.

Own a piece of history. Wear the elegance of Lucknow.

💫 Looking for Authentic Lucknowi Chikankari? Explore our handcrafted collection today!